Specific product: Anti-sway

Driver assistance system

The action time of operators can represent up to 20% of the production cycle time. AES anti-sway system reduces parasitic movement of the handled load, relieves the driver of the delicate control of load sways, increases productivity and allows the driver to be quieter and less fatigued. This system also reduces mechanical stress then decreases maintenance costs. It can be installed on a new crane as part of a new project or added on a crane already in operation.

Our anti-sway system is installed directly on the PLC which controls all the movements of the crane. The system developed by AES by using a mathematical modeling of the movements’ speeds which generate sways.

Problems

The sway of the load is mainly the consequence of:

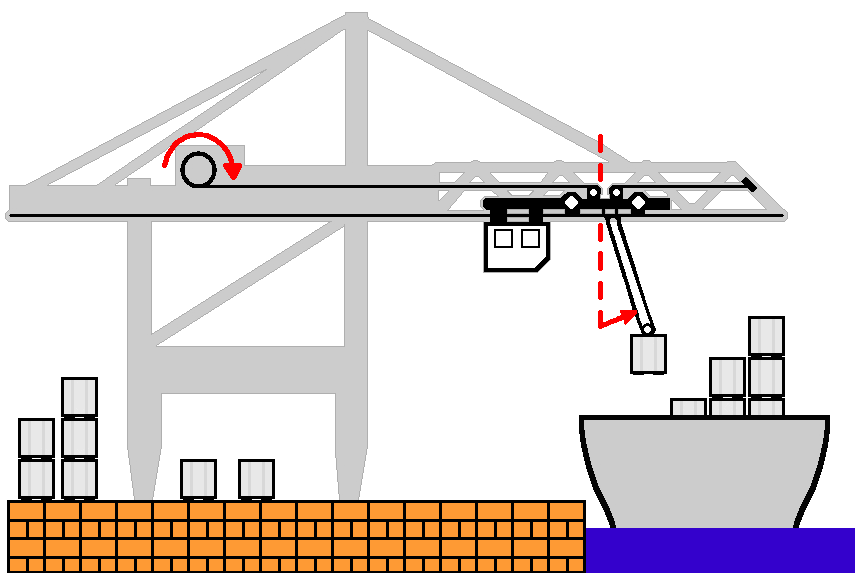

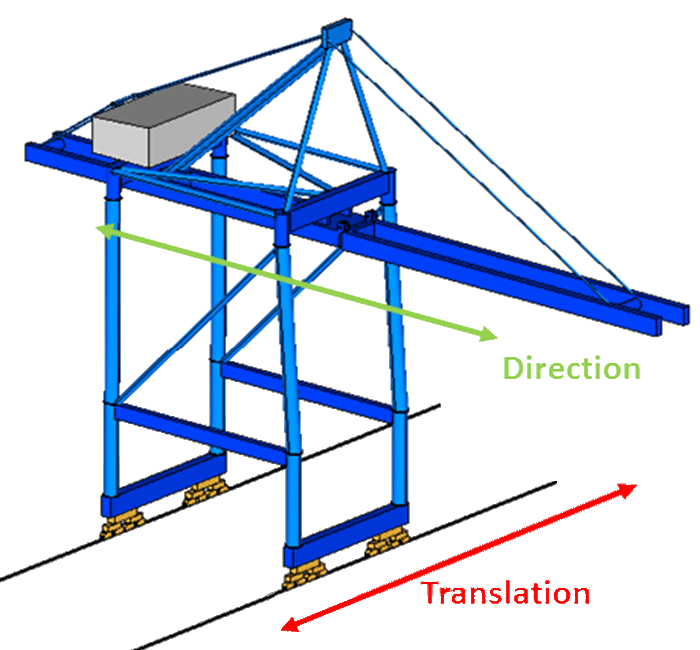

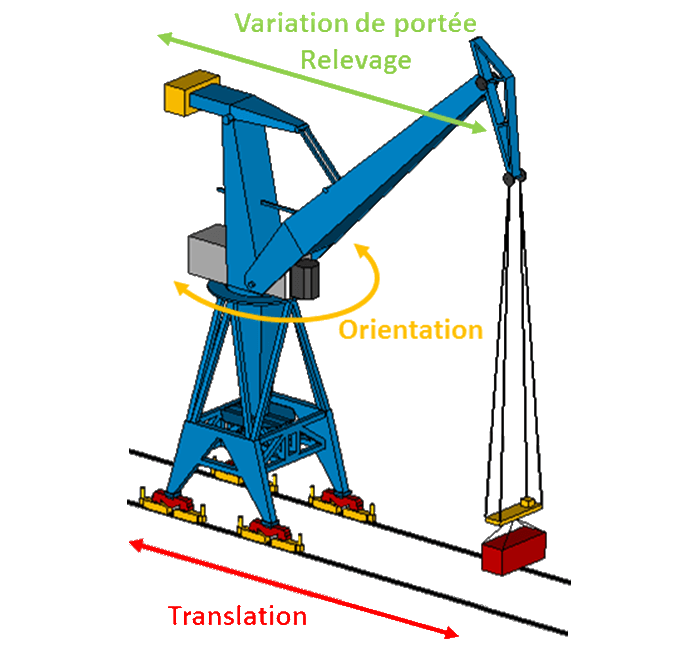

- Movements of the cranes:

- directional movement,

- horizontal movement,

- orientation movement,

- translation movement.

- Wind force on the load.

Gantry movement

Crane movement

Chosen solution

AES's anti-sway system meets the following requirements:

- No additional time at the theoretical minimum cycle,

- Efficiency during simultaneous movements,

- Easy and quick use,

- Reduced (almost zero) maintenance,

- Non-intrusive for the pilot.

The system used for the anti-sway driving is open-loop type. The used method is the multiple pulse one. This multiple pulse method acts on the controller to reduce sways. The suppression of the load sway is obtained with a reference signal applied to the controller signal. Simulations allow the validation of the settings of the different levels, the pulse values and the various parameters.

Results on driving

The use of the anti-sway slightly modifies the driving but after a short adaptation period of about 5 tests, the cycle time is decreased, the movements are more flexible and the fatigue is reduced. The 4 pulses method is the best in theory but, in operation, it generates too much sliding of the carriage, and a feeling of no control of the movement. The double impulse method is generally preferred in operation.

Summary

AES anti-sway system reduces parasitic movement of the handled load. The main characteristics of the system are not to generate additional time to the theoretical minimum cycle and to keep all its efficiency during the simultaneous movements. It is a non-intrusive device, adjustable sensitivity by the driver, easy and quick to use and reduced or no maintenance. The program block (anti-sway) is inserted in the PLC and directly controls the setpoint and the running commands of the motion controllers. The system principle is based on the multiple pulse method. The integration of the anti-sway on a crane brings a softening of the movements and helps to reduce the fatigue of the drivers.

Do not hesitate to contact us further information about our products.