Specific product: SSCC

Kinematic Chain Monitoring System

The SSCC (Kinematic Chain Monitoring System) makes it possible to ensure the safety of Kinematic Chain in case of breakage or malfunction. The main diagnosed failures are:

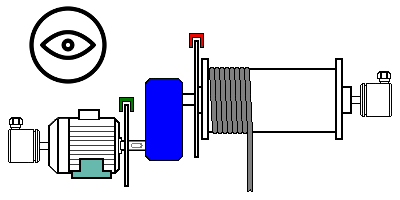

The considered Kinematic Chain consists of a motor, one or more service brakes, a gearbox or multiplier, a drum with one or more safety brakes. The motor axis and drum axis are equipped with incremental encoders to analyze the speed and direction of rotation of the shafts.

Defect management

Functional defects

- Static deviation

- Dynamic deviation

- Overspeed

- Desynchronization

- Emergency stop

- Zero speed

- Default sense

Optional faults

- Service brake fault

- Motor temperature threshold exceeded

- Gearbox temperature threshold exceeded

- Allowed emptying time pasted

- Drum speed below the threshold of underspeed

Hardware defects

In case of presence of at least one of the functional faults, one of the optional faults or one of the preceding material faults, the 2 control outputs of the safety brakes open. A default acknowledgment is then necessary, followed by a self-test, in order to rearm the SSCC. Parameterizable alarms are triggered in the following situations:

- Motor temperature threshold exceeded

- Gearbox temperature threshold exceeded

- Drum speed below the threshold of underspeed

Additional features

Additional functionalities have been integrated to facilitate the implementation and diagnosis of SSCC:

- Self-test: To validate the correct operation of the equipment

- Learning: Allows the acquisition of the mechanical and functional characteristics of the kinematic chain

- Reset: Reloading parameters and settings to their default values

Optional function:

- Synchronization: Several SSCCs can be connected to each other via the Safe Ethernet network to control the synchronization of several drivelines.

Products

AES commercializes 3 types of SSCC (in the form of a product to be mounted on a rail or in the form of a box integrating an operator dialogue):

- SSCC TCP / IP Ethernet communication (SSCC ETH)

- SSCC Slave Modbus Communication (SSCC MDB)

- SSCC Slave Profibus Communication (SSCC PFB)

The AES SSCC consists of a Schneider Electric brand, SIL3 level safety PLC, compliant with IEC61508 standard.

Summary

The SSCC (Kinematic Chain Monitoring System) is a system for securing the drive train in case of breakage or malfunction of the drive train. It consists of a SIL3 safety PLC according to IEC61508 mounted on a rail or in the form of a box incorporating an operator dialogue. This system makes it possible to detect the following faults: static and dynamic unwinding, overspeed, desynchronization, emergency stop, zero speed, defect of direction. It could also incorporate features of self-test, learning, reset and synchronization.

Do not hesitate to contact us further information about our products.