Specific product: Digilife ©

Fatigue monitoring of a hoist equipment (AQUASS & AES)

Digilife © is a device for fatigue monitoring, embedded on a new crane or on a crane in service, whose main functions are:

Context

The phenomenon of fatigue damage is, on the one hand, from the extent of stresses experienced by an element during each cycle, and on the other hand, from the number of stress cycles. The maximum lifespan of hoisting equipment is defined for each use in the FEM rules or in EN 13001 by:

- a maximum number of solicitation cycles;

- a spectrum of relative stress range, a histogram of the occurrence frequency of different values about the relative stress ranges (with respect to the nominal load).

The value of the ratio of damages (ratio of the accumulation of the damages passed to the maximum damage of design) is called fatigue index. This value serves as the basis for defining the content of special evolutions, defined in « Recommendations for hoisting devices at ports » established by CETMEF.

Behavior

Digilife © does not affect operations of the crane and therefore no discomfort can be caused by its malfunction. Its autonomy is sufficient to self-diagnose and warn operators of any internal or environmental malfunction. An internal malfunction does not affect the storage in memory of the calculated results and parameters.

Fatigue indices, load or moment factors, the number of hoist and fatigue cycles, and the number of hours of operation (for kinematic chains) are the main parameters of engagement for special evaluation.

Digilife © outputs the fatigue index of the hoisting equipment and its kinematic chains. Monitoring these factors over time is a very useful management tool for the equipment manager (especially for conditional maintenance operations).

Composition

The fatigue monitoring device, consisting mainly of Schneider Electric brand equipment, includes:

- a regulated power equipment

- a M580 processor - acquisition and processing equipment processes all the data provided by the sensors installed on the gantry

- a communication card

- a program memory card and a high-density data memory

- a device for saving results and parameters

- a link (radio or optical fiber) connecting the embedded PLC and a PC on-shore

- All components are integrated into a standard dimensions IP55 cabinet

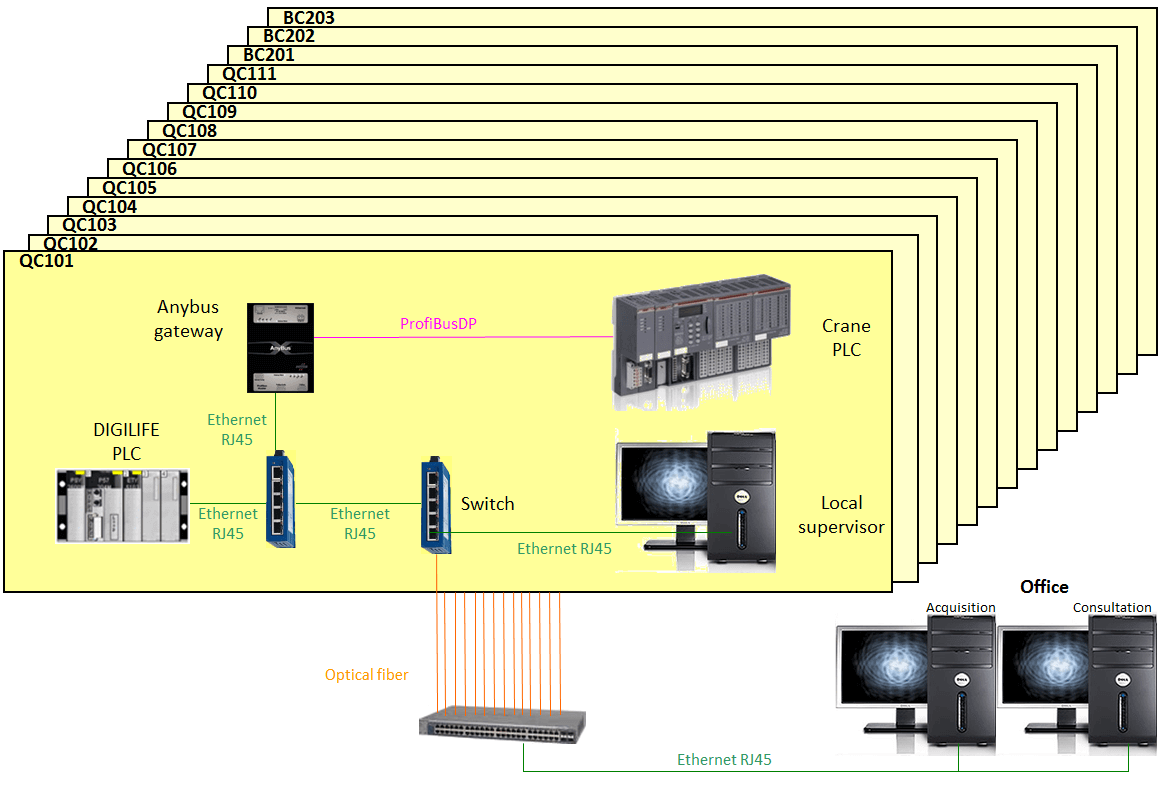

Example of an installation diagram for 14 STS cranes (Port of Rotterdam - 2015)

The device is self-sufficient for the specific functions of conservation of accumulations of fatigue damage. The link with the on-shore PC will enable:

- the remote maintenance of device,

- the management of operating parameters which are useful for maintenance,

- the output of the operating statistics,

- the transmission of various operating parameters of a particular event (significant overload of winch, significant load differential of winch, anti-snag defect, etc.) in the form of continuous variation, for a few seconds straddling the moment of the incident.

The fatigue monitoring device is standardized. The crane-specific setting is made during commissioning.

The information from various sensors makes it possible to define the working cycles and, thanks to a complementary calculation, the actual fatigue cycles (load variations during the hoisting cycle). These information enables also calculate:

- the fatigue index of the crane and its kinematic chains as a whole by adding up past fatigue damage,

- the various other parameters necessary to reconstruct the individual damages of the elements and assemblies of the structure.

Results

There’s 5 types of different results and output parameters of Digilife ©:

- which is necessary to know the state of conventional damage to the crane and the kinematic chains, essential indicators for the activation of various operations of special evaluations and numerous controls of the maintenance plan,

- which, in actual operating conditions, provides information on the stress spectrum factors and the actual number of fatigue cycles and make it possible to carry out calculations of the residual life of critical elements and assemblies,

- which provides information on the commercial operation of the CTS crane, (number of handled containers per type, statistics on the weight of handled containers, etc.),

- which initiates maintenance operations or conditional checks,

- which is useful for troubleshooting assistance during a particular event (in the form of curves for a few seconds straddling the time of the incident).

With the exception of the outputs in the form of continuous recording of the operating parameters during an incident, whatever happens, all other parameters are kept in memory. At any time, the value of these different parameters can be transmitted to the ashore PC.

Registration

The various collected information is transmitted to a PC in order to be processed and saved. The different types of registrations are:

- Current values upon request (the current value integrates the different values of each cycle since the zero cycle).

- Current values with fixed configurable periodicity (the current value integrates the different values of each cycle since the zero cycle).

- Current values for a fixed duration with a fixed parameterized period (the current value integrates the different values of each cycle from the beginning to the end of the determined duration).

- Current values for a variable duration defined by a start and an end mark (the current value integrates the different values of each cycle between the two tops).

- Instantaneous preselected values during a triggering event. (Duration: 5 s spread equally before and after the event).

Summary

Digilife is a real-time monitoring system for the aging (fatigue) of hoisting devices developed by AES and Aquass. It is a polyvalent and patented equipment installed permanently on a new crane or on a crane already in service. It remotely stores and delivers the aging level of frames and kinematic chains as well as commercial exploitation data. The exploitation of the results makes it possible to guarantee the safety of the personnel as well as the integrity of the crane.

Do not hesitate to contact us further information about our products.